Ecosense Decontamination Services Technology

A Risk Assessment Based Approach to Selecting Technology

Many organizations use risk assessment methods to manage their business and comply with industry regulations. Google the term “risk assessment” and you are likely to find a definition along the lines of “A systematic process of evaluating the potential risks that may be involved in a projected activity or undertaking”. In other words:

Select a Technology that Delivers the Performance you Require in Real World Operating Conditions

Based upon our experience, we couldn’t agree more. Unique operating conditions can hinder the performance of many technologies in less than ideal conditions. Unfortunately, there is no “silver bullet” or “one size fits all” technology that works in every situation. If it were only that simple! But the fact is, typical operating conditions in the “real world” can be vastly different from the ideal conditions in a testing lab.

We get it … Selecting the proper decontamination approach can be a confusing and a frustrating experience. Especially when you have little margin for error and have to get it right the first time. Our mission is to listen and help you select the best decontamination solution that meets your needs.

Real World Selection Considerations

Efficacy Factors

Problem Areas

Safety Considerations

Customer Needs

“Given the choice of improving technology or improving human behavior, technology is the better choice” – Dr. Bob Weinstein

We’ve cultivated decontamination options that vary in strength or efficacy levels, ranging from sterilization services that deliver a log6 (99.9999%) bio-burden reduction, to lower efficacy decontamination treatments that provide disinfection or sanitization results. In the majority of the situations that we face, we’ve found that the technologies listed below deliver the best results in “real world” operating conditions.

Click + To Expand or Scroll Down for Detailed Information

VISUALY CLEAN AND SANITIZATION RESULTS - Surface Contamination

Electrostatic Spraying , Chemical Foaming, Dry Vapor Steam Cleaning and Pressure Washing Solutions. Basic decontamination solutions or supplemental cleaning options that properly prepare a surface prior to a sterilization or disinfection treatmentEffective

We can achieve a 99.9999% bio-burden reduction of spores, bacteria, viruses and fungi hiding in difficult to reach areas.

Fast

Our treatments are applied quickly and efficiently, guaranteeing minimal downtime at your facility.

Safe

Our preferred products have low toxicity ratings without harmful chemical residuals, which helps keep everyone safe.

Affordable

Our services are affordable and significantly less expensive than the cost of a recall or outbreak.

STERILIZATION RESULTS

Airborne and Surface Contamination

Decontamination and Sterilization with ClorDiSys Chlorine Dioxide Gas

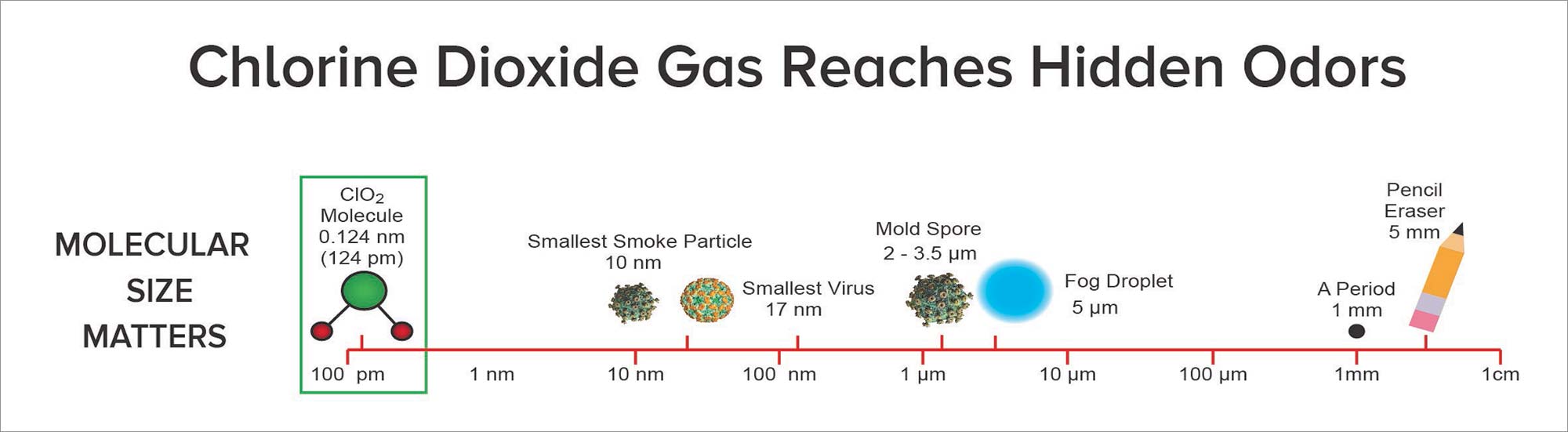

The ClorDiSys system is considered to be the industries’ most effective approach for eliminating harmful microorganisms that reside in difficult to reach areas and in high-risk situations where adverse biological occurrences have significant repercussions. As a true gas with even distribution characteristics and unparalleled penetration ability, ClorDiSys’ efficacy is not compromised by complex building geometries, intricate equipment designs, and common environmental conditions that limit the effectiveness of other technologies.

Did you know? ClorDiSys technology was originally developed to sterilize implantable contact lens, earning FDA approval as a residual free gas generation method.

ClorDiSys Technology Consistently Performs in Real World Operating Conditions

Compared to other technologies, no cycle development time or validation phase is required in challenging applications prior to decontamination. This is an important factor when responding to high-risk decontamination situations where efficacy, time and cost are important considerations. When faced with unknown risks, the ClorDiSys method is the clear choice.

Target Audience

- Highly regulated industries where microbial contamination has severe consequences

- Applications where biological contamination can lead to death or contribute to serious and costly infections

- Customers where a publicized occurrence can lead to a significant loss of profits, enterprise value and brand value

- Progressive companies seeking to mitigate risk and establish a robust validation process that limits legal exposure

- Cost conscious operators seeking to improve utilization rates, reduce downtime and reduce manual cleaning costs

- Industries and customers desiring EPA, FDA, USDA and ORMI organic approvals

- Customers with challenging operating conditions that may impede the ability to achieve either sterilization, disinfection or sanitization results

Validated results in challenging applications

- Capabilities range from treating individual pieces of equipment and single rooms to large buildings and confined spaces

- Worldwide track record of decontaminating challenging high-profile projects with extensive 3rd party validation

- Registered with the EPA as a sterilant capable of killing all spores, bacteria, viruses, and fungi

- Effective in destroying hard to kill beta lactams, pinworm eggs and PCR Amplicons

- Capable of inactivating many API’s and high-potency protein and amino acid based compounds. Inquire for specifics

- Nano size gas particles allows for complete decontamination in even the smallest and most difficult to access areas, including intricate equipment, HVAC systems, Hepa filters and inside long pipe runs

- Large facilities up to 4,400,000 Cu ft with complex geometries can be decontaminated in one cycle

- Results verified by using biological indicators placed in difficult to reach places which are inoculated with bacterial spores (Geobacilius stearothermophilus 106) known to be among the most difficult to destroy

- Documentation validating the procedural, chemical and biological results are provided with each treatment

Fast performance in real world situations

- No time consuming and costly cycle development step is required

- Flexible operating parameters where efficacy is not compromised by the presence of light organic matter, biofilm, water residue and temperature/humidity gradients.

- Time and efficacy is not affected by equipment loading patterns or the volume of contents within the decontamination zone

- Much faster treatment time when compared to either Vapor Phase Hydrogen Peroxide or Formaldehyde

Safe on materials with minimal environmental impact

- Safe treatment method rated as a Non-Carcinogen by the IARC and ACGIH where no harmful byproducts are generated or left behind

- Proprietary pH neutral and residue free generation method permits the sterilization of high-value critical equipment, including electronics, without the risk of corrosion or premature failure

- Low environmental impact technology earning approved listing on the USDA’s National Organic Programs list of Allowed and Prohibited Substances

Put Us To The Test: Small batch testing is available to confirm any concerns regarding material compatibility

Sterilization Resources

Biological Efficacy of ClorDiSys Chlorine Dioxide Gas

ClorDiSys Chlorine Dioxide Gas Decontamination Services

ClorDiSys Material Compatibility Brochure

Spiral Freezer Decontamination Brochure

Contract Sterilization with Chlorine Dioxide Gas

Customer List

SANITIZATION AND DISINFECTION RESULTS

Airborne and Surface Contamination

The consequences to businesses and institutions experiencing biological contamination in lightly to moderately regulated industries can be just as significant as those operating in highly regulated industries. While the sterility requirements in many of these industries are less stringent, that doesn’t mean that our decontamination approach is any less stringent.

Our disinfection or sanitization technologies typically deliver a log3 to log5 (99.9%-99.999%) bio-burden reduction in low-moderate risk industries. Performance can be validated using a variety of methods including ATP swabbing, microbial swabbing, chemical indicators and biological indicators.

Target Audience

- Light to moderately regulated industries where microbial contamination can have moderate consequences

- Applications where avoidable biological contamination can lead to moderate or serious infections

- Customers where a publicized occurrence can damage their reputation and have lasting repercussions

- Proactive companies or institutions seeking to mitigate risk and protect the health of all stakeholders

- Operations seeking to improve utilization rates, reduce downtime and reduce manual cleaning processes

- Customers with lower risk operating conditions

Did you know? Our dry fog technology was developed in response to the international pharmaceutical communities’ need for a cost effective solution to decontaminate cleanrooms on a monthly basis.

Dry Fogging for Low to Intermediate Level Efficacy Requirements

Dry fogging has emerged as a popular method for decontaminating small to medium sized areas or confined spaces where time, cost, material compatibility and flexibility are important considerations. For these reasons, the technology has gained prominence in many industries as a viable alternative to chemical decontamination methods utilizing vaporized hydrogen peroxide (VHP) and micro-condensation. Today, Dry Fogging is used in all industries that require low to intermediate level efficacy results, fast turnaround times, and cost effective decontamination solutions.

As the name implies, dry fogging avoids wetting the surface. This minimizes potential material compatibility issues, and avoids the long aeration cycles typical of other methods. No pre-conditioning of the room is required either, further reducing the treatment time. Using a variety of dry fogging systems permits us to use different chemicals, allowing us to match the appropriate disinfectant with each client’s unique requirements. All this adds up to providing excellent value for our clients.

Validated results in lower-risk applications

- Effective in controlling or destroying bacteria, viruses, fungi and C-diff spores in the appropriate setting

- Wide variety of disinfectant choices are available

- Achieves sanitation and disinfection results in small to medium size spaces

- Efficacy results can be verified using biological indicators, dosage monitoring devices and swabbing options

Fast results without the cost of a VHP treatment

- Fast equipment set-up and minimal space pre-conditioning requirements allow us to treat a space quickly and pass along the cost savings to our clients

- Dry fog technology minimizes the time consuming aeration cycle compared to VHP

- Ultra-fine dry fog quickly fills the space and remains suspended in the air for the proper amount of time, insuring that adequate contact times and efficacy results are achieved

Flexible treatment alternatives provide excellent value

- A wide variety of EPA approved, low toxicity, non-corrosive disinfectants and sanitizers are available, including Hydrogen Peroxide, Peracedic Acid/Hydrogen Peroxide blends, Chlorine Dioxide, Pharmaceutical grades, etc.

- Our dry fogging equipment is suitable for use in applications with autoclave requirements

- Dry fogging can be combined with any of our treatment methods to meet each client’s performance and budgetary requirements

Wet Fogging for Low to Intermediate Level Efficacy Requirements

The Ecosense Company uses Wet Fogging equipment to sanitize or disinfect small to large size areas where time and cost are important considerations. In many applications, the technology is used as a viable alternative to more costly methods such as stationary aerosolized fogging or vaporized hydrogen peroxide (VHP). Wet fogging is used in all industries that require low to intermediate level efficacy results, fast turnaround times and cost effective decontamination solutions.

The Ecosense Company uses Wet Fogging equipment to sanitize or disinfect small to large size areas where time and cost are important considerations. In many applications, the technology is used as a viable alternative to more costly methods such as stationary aerosolized fogging or vaporized hydrogen peroxide (VHP). Wet fogging is used in all industries that require low to intermediate level efficacy results, fast turnaround times and cost effective decontamination solutions.

In the wet fogging process, a skilled technician applies an ultra fine disinfectant layer to the surface. Handheld foggers are used, so that a trained technician is able to reach more surfaces than with a stationary fogger by opening drawers, cabinets and enclosures, and changing the angle of application to minimize missing shadow areas. The wet fogging process is also used for remediating airborne contamination. By aerosolizing disinfectants throughout the entire airspace, lower level airborne contamination and odors can be controlled.

Fast results without a costly treatment

- Effective in controlling or destroying bacteria, viruses, fungi, C-diff spores and odors in the appropriate setting

- Wide variety of disinfectant choices are available

- Achieves sanitation and disinfection results in small to large size spaces

- Efficacy results can be verified using the ATP process or microbial swabbing

- Used in lower risk applications that don’t require 100% coverage in microscopic crevices or difficult to reach areas

VISUALLY CLEAN AND SANITIZATION RESULTS

Surface Contamination

The universal decontamination premise is that you must start with a relatively clean surface before you begin treatment. Any potential interference that may impede the ability to achieve sterilization, disinfection or sanitization results must be eliminated. This means that excess bio-burden must be removed, as many chemical agents can’t adequately reach or penetrate dirty or soiled loads. Additionally, soiled areas can also react with, or absorb a decontamination agent, minimizing the agent’s efficacy and the outcome of the treatment.

We request that clients remove gross contamination and any residual product matter from the treatment zone before we initiate treatment. In practice, we find that some of our client’s don’t have the adequate resources to perform these tasks in-house. As a result, we offer a variety of supplemental services on a case by case basis in conjunction with our sterilization and disinfection services.

Supplemental Decontamination Treatment Offerings

Chemical Foaming: Removes biofilm and stubborn contamination in challenging areas

Dry Vapor Steam Cleaning: Decontamination of moisture sensitive items

Pressure Washing: Removes heavy soils in moisture tolerant applications

Electrostatic Spaying Services

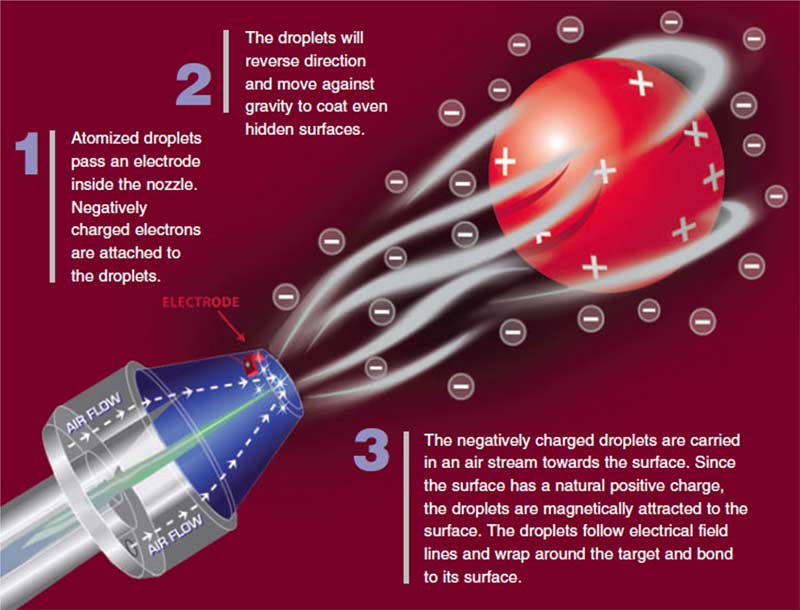

The Ecosense Company utilizes electrostatic sprayers in applications where the surfaces have been pre-cleaned and have a low soil level. We’ve found that the electrostatic sprayer is one of the most effective and economical application technologies available for achieving sanitization results in lower risk applications. Capable of delivering a wide range of disinfectants, the electrostatic sprayer takes a single drop of liquid and turns it into 900 charged droplets.

Those charged droplets are then attracted to the object or surface requiring disinfection, defying gravity in the process. Because of this, the electrostatic sprayer is able to reach areas that are frequently missed by traditional spray and wipe disinfection methods, including the underside and backside of objects that harbor contamination.

When it comes to the droplets, size really does matter. Turning a single drop into 900 and propelling it at high velocity, means that you use much less disinfectant in the process. Ecosense clients can now afford to use disinfectants with the highest efficacy and safety ratings that would otherwise be too expensive if applied with traditional methods.

The Benefits of Electrostatic Spraying

- Smaller droplets mean less product usage and lower cost

- Charged particles easily cover hard to reach places

- Proper application typically ensures 80% to 100% surface coverage

- Chemical choices that work in the presence of light organic matter

- Reduces the potential for human error

Chemical Foaming Services

The Ecosense Company utilizes the chemical foaming process to properly clean and prepare surfaces prior to more advanced decontamination treatments, or for separate sanitization treatments. One of the greatest challenges in many cleaning applications that rely solely on using liquids, is the inability to maintain the proper chemical concentration level and the specified dwell time over the duration of the entire treatment. This issue is more pronounced when treating odd shaped items or vertical surfaces prone to liquid run-off. The thick, clingy nature of foam allows us to overcome many of these barriers.

The Ecosense Company utilizes the chemical foaming process to properly clean and prepare surfaces prior to more advanced decontamination treatments, or for separate sanitization treatments. One of the greatest challenges in many cleaning applications that rely solely on using liquids, is the inability to maintain the proper chemical concentration level and the specified dwell time over the duration of the entire treatment. This issue is more pronounced when treating odd shaped items or vertical surfaces prone to liquid run-off. The thick, clingy nature of foam allows us to overcome many of these barriers.

We select cleaning foams based upon a number of factors including the type of contamination we are seeking to remove, compatibility with surface materials, and their environmental impact. Our preference is to use environmentally friendly products such as enzymatic cleaners which are rapidly gaining prominence in critical decontamination applications. However, we also use alkaline cleaners to remove acid debris (pH<7) such as grease, oils and sugars, as well as acid based cleaners to remove alkaline debris (pH>7) such as calcium, rust, scale, oxide lime build-up and bicarbonates among others.

The Ecosense Company’s foaming process is also compatible with a select number of EPA registered disinfectants. In the appropriate application, our foaming process can deliver sanitization and disinfection level results in lieu of more advanced treatment methods.

Of particular importance, chemical foaming has been proven to be a very powerful tool for removing mature biofilms. When used in conjunction with our ClorDiSys decontamination method, this combination effectively addresses the source of many unpredictable spikes in microbial test results associated with biofilm dispersal and food recalls. In many food production environments, reducing the biofilm population can also greatly slow the product degradation cycle and significantly improve product shelf life. We offer highly-effective curative and preventative biofilm remediation programs that compliment your current sanitization programs.

The Benefits of Chemical Foaming

- Effective in removing a wide variety of stubborn contamination

- Can be used to clean and/or sanitize difficult to reach surfaces

- Wide variety of EPA registered chemical choices

- Environmentally friendly enzymatic and organic approved options

- Very effective at removing and controlling biofilms

Dry Vapor Steam Cleaning Services

The Ecosense Company utilizes a dry vapor steam cleaning process for removing difficult contamination and encrusted product residues from surfaces in moisture sensitive applications. Our dry vapor steam cleaning equipment utilizes a combination of heat, low moisture, pressure and suction to loosen and remove contamination. In some applications, dry vapor steam held for the proper dwell time will deliver sanitization or disinfection level results. Our process is suitable to use in a wide variety of applications, ranging from cleaning single pieces of pharmaceutical or food processing equipment, to cleaning surfaces in small to medium sized spaces in preparation for more advanced sterilization or disinfection treatments.

The Ecosense Company utilizes a dry vapor steam cleaning process for removing difficult contamination and encrusted product residues from surfaces in moisture sensitive applications. Our dry vapor steam cleaning equipment utilizes a combination of heat, low moisture, pressure and suction to loosen and remove contamination. In some applications, dry vapor steam held for the proper dwell time will deliver sanitization or disinfection level results. Our process is suitable to use in a wide variety of applications, ranging from cleaning single pieces of pharmaceutical or food processing equipment, to cleaning surfaces in small to medium sized spaces in preparation for more advanced sterilization or disinfection treatments.

During the dry vapor steam cleaning process, less than 5% water content contacts the surface, hence the term “dry steam”. This makes it suitable to use in moisture sensitive applications such as equipment decontamination, where electrical components are present. During the cleaning process, steam is heated up to 364 0F and delivered at pressures up to 115 PSI. For stubborn contamination, chemicals can be injected to facilitate the cleaning process. Finally, a built-in HEPA vacuum aids in collecting contamination and avoiding cross contamination.

The Benefits of Dry Vapor Steam Cleaning

- Effective in removing a wide variety of stubborn contamination

- Can be used in moisture sensitive environments

- Environmentally friendly water vapors

- Water vapors can be augmented with cleaning solutions

- Can deliver sanitization or disinfection results in some applications

Pressure Washing Cleaning Services

The Ecosense Company uses a variety of different pressure washing systems for removing heavy contamination in moisture tolerant applications. We use heated water systems as well as systems that operate at ambient water temperatures and utilize both low and high pressure delivery methods. Food processing equipment, transportation vessels, IBC’s and any surface that is designed to be wash downed are good candidates for pressure washing. When a cleaning agent must be added to the water, we prefer to use environmentally friendly chemical surfactants that comply with the strictest water discharge requirements.

The Ecosense Company uses a variety of different pressure washing systems for removing heavy contamination in moisture tolerant applications. We use heated water systems as well as systems that operate at ambient water temperatures and utilize both low and high pressure delivery methods. Food processing equipment, transportation vessels, IBC’s and any surface that is designed to be wash downed are good candidates for pressure washing. When a cleaning agent must be added to the water, we prefer to use environmentally friendly chemical surfactants that comply with the strictest water discharge requirements.

The Benefits of Pressure Washing

- Effective in removing a wide variety of contamination

- Fast and cost effective treatment method

- Environmentally friendly water

- Water can be augmented with cleaning solutions

- Water temperature and pressure can be regulated

ODOR REMOVAL RESULTS

Airborne and Surface Contamination

It is a commonly held belief in some quarters that odor removal is a simple and straightforward process requiring little training or expertise. In our experience, odor remediation is far from a simple or straightforward process. In fact, removing challenging odors can often be as difficult as achieving sterilization results in many high-risk critical industries. Considerable expertise blending technical know-how with the appropriate technology is often required in order to successfully remove many challenging odors in a safe manner.

Odor remediation typically involves using powerful chemicals and/or gases in a commercial or residential setting. In this environment, construction materials and porous contents that weren’t designed to withstand the effects of many decontamination technologies are often present. Additionally, commercial and residential odor remediation is usually performed in less than ideal atmospheric conditions, compounded by the presence of organic matter, cellulose materials and other absorbents that work to impede the odor removal process.

Having performed over 500 odor removal projects, we understand how to successfully remediate difficult odors in a safe fashion. We know what technologies work and don’t work. We’ve used all the different odor removal technologies at some point, but have found that two in particular, chlorine dioxide and hydrogen peroxide, deliver the best combination of performance and safety.

Chlorine Dioxide Odor Removal Technology

The Ecosense Company uses chlorine dioxide products for difficult odor remediation projects. Not to be confused with chlorine or bleach, our chlorine dioxide products are non-carcinogenic with pH neutral properties, making them a safer alternative for use in commercial and residential settings. No harmful residues are generated or left behind. Of particular importance, chlorine dioxide is the chemical option which is least affected by the presence of organic matter, cellulose materials and other absorbents that commonly work to impede the odor removal process.

We often use both aqueous chlorine dioxide solution and chlorine dioxide gas together on many odor remediation projects as a one-two punch. Chlorine dioxide gas is liquid soluble, meaning that it doesn’t lose its strength in the presence of liquids, and actually supercharges the aqueous chlorine dioxide solution’s ability to penetrate and destroy odiferous bacteria and fungus. In our experience, chlorine dioxide gas fumigation is the most effective method for destroying odors in hidden or difficult to reach areas that are prevalent in odor remediation projects.

Our chlorine dioxide products can be scaled up to provide fast treatment times on large jobs and easily adjusted to remediate the strongest residential odors. Insurance companies appreciate the cost savings they enjoy by reducing additional living expense (ALE) reimbursements, business interruption (BI) insurance claims, and odor related contents replacement claims. Discerning homeowners enjoy The Ecosense Company’s ability to restore their home’s environment and value in a professional manner.

Our chlorine dioxide products can be scaled up to provide fast treatment times on large jobs and easily adjusted to remediate the strongest residential odors. Insurance companies appreciate the cost savings they enjoy by reducing additional living expense (ALE) reimbursements, business interruption (BI) insurance claims, and odor related contents replacement claims. Discerning homeowners enjoy The Ecosense Company’s ability to restore their home’s environment and value in a professional manner.

Chlorine Dioxide Odor Removal Benefits

- High performance in challenging applications

- Strength can be adjusted for strong odors

- Easily scaled up to treat large projects

- Safe pH neutral, non-carcinogenic with no residue

- EPA registered products with organic approvals

Hydrogen Peroxide Odor Removal Technology

The Ecosense Company uses various hydrogen peroxide products and delivery methods in lower level odor remediation projects. Similar to our chlorine dioxide technology, hydrogen peroxide is non-carcinogenic to humans and enjoys a well deserved reputation as a versatile odor remediation solution.

Our hydrogen peroxide solutions are appropriate to use on both hard and many soft porous surfaces with minimal compatibility issues. No harmful chemical residue is generated or left behind. However, hydrogen peroxide does not share the unique properties of chlorine dioxide where performance is not significantly compromised by the presence of organic material or liquids. As a result, we use hydrogen peroxide in lower level odor remediation projects or applications where there is no visual soiling, residual water deposits, or contamination present.

Hydrogen Peroxide Odor Removal Benefits

- High performance in cleaner environments

- Dry fog, wet fog and spray delivery methods

- Suitable for treating small to medium size areas

- Safe pH neutral, non-carcinogenic with no residue

- EPA registered products

A New Professional Approach to and Age Old Problem